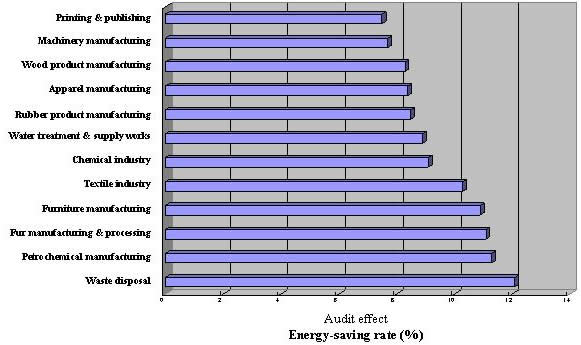

Energy-saving effect by 1 day-audit

(Average energy-saving rate by industry)

(Average energy-saving rate by industry)

| AEEC Home | Training Index | Index | Top | Previous | Next |

| METI/ECCJ/AOTS Training Program | Indonesia |

Energy-saving effect by 1 day-audit (Average energy-saving rate by industry) |

|

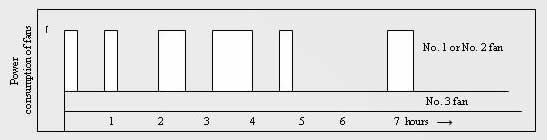

Case example of audit (1): Water supplying works |

Problems:

|

Case example of audit (2): Food manufacturing industry |

Problems:

|

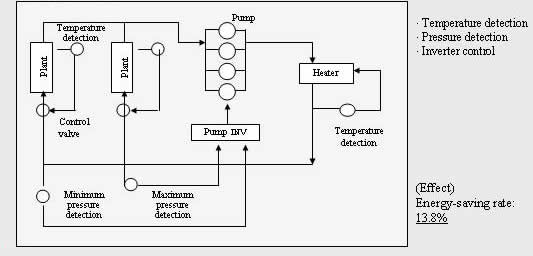

Case example of audit (3): Petrochemical product manufacturing |

Problems:

|

| 14/23 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |