Public Programs on Energy Conservation Auditing Performed by ECCJ

| AEEC Home | Training Index | Index | Top | Previous | Next |

| METI/ECCJ/AOTS Training Program | Vietnam |

6-2. For industrial sector |

Public Programs on Energy Conservation Auditing Performed by ECCJ |

|

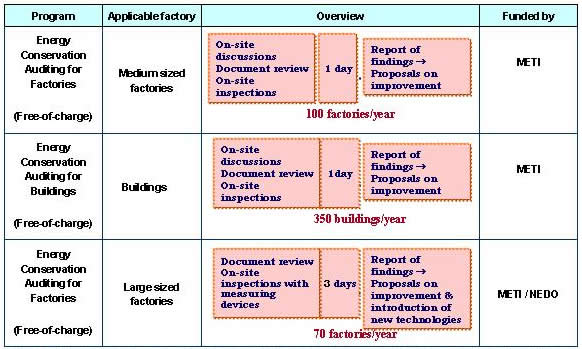

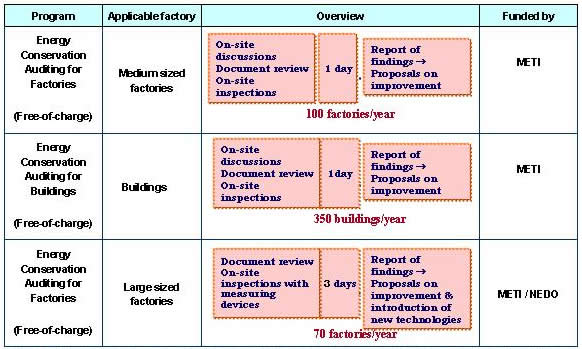

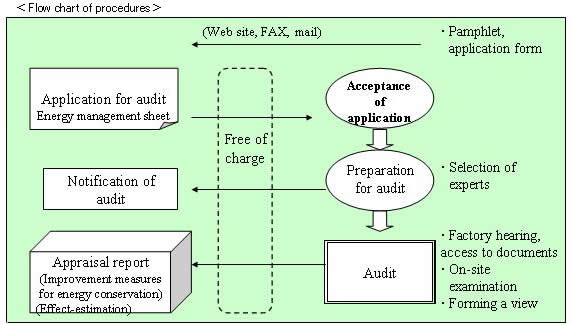

1 day-Energy Audit for Factories and Buildings

|

|

Details of investigation/audit conducted (Examples of general management matters and steam system) |

|

<Steam system>

|

Results of 1 day-audit for factories |

| Number of factories audited: 1,742 (Fiscal years 1997 - 2003) (Details) Electromechanical apparatus manufacturing Food manufacturing Chemical industry Transport equipment manufacturing Plastic products manufacturing Metal product manufacturing Water treatment & supply works General machinery and apparatus manufacturing Ceramic/Cement product manufacturing Precision machinery and apparatus manufacturing Nonferrous metal manufacturing Textile industry (Others) |

| 19/33 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

| Copyright(C) ECCJ 1996-2019 |