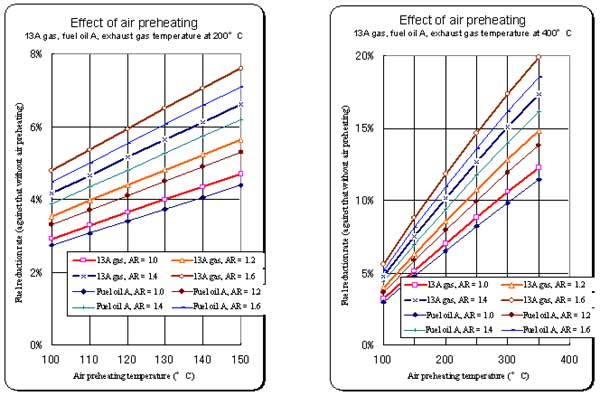

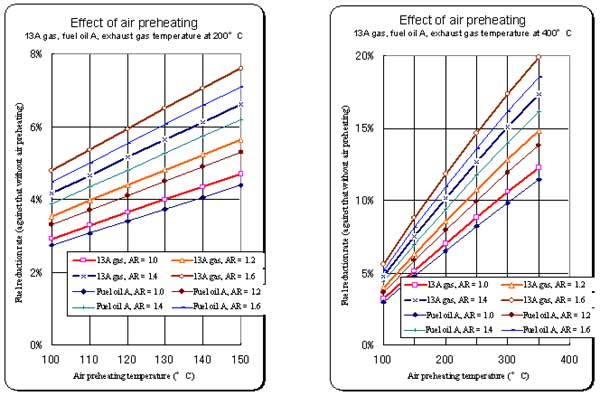

Effect of air preheating

- If the heat contained in the exhaust gas is recovered by installing an air preheater, the temperature of the exhaust gas is lowered and the required fuel is reduced.

| AEEC Home | Training Index | Index | Top | Previous | Next |

| METI/ECCJ/AOTS Training Program | Indonesia |

Effect of air preheating |

|

Criteria for exhaust gas temperature (the Law Concerning Rational Use of Energy) |

|||||||||||||||||||||||||||||||||||||||||||

Criteria for boilers, Standard / target exhaust gas temperature

|

|||||||||||||||||||||||||||||||||||||||||||

Criteria for factories (the Law Concerning Rational Use of Energy) |

|||

|

Energy Conservation Improvements |

||

|

---2 ---3 ---4 ---6 ---7 ---8 ---9 |

|

| 6/14 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |