7.Energy-Saving

Labeling System

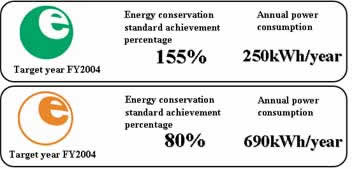

| - The energy-saving labeling system has been introduced to inform consumers of energy efficiency of home appliances and promote energy efficient products. |

Examples

of energy-saving labeling |

| As of April 2004, the labeling is applied to the following 10 products: air conditioners, fluorescent lights, TV sets, electric refrigerators/freezers, space heaters, gas cooking appliances, gas water heaters, oil water heaters and electric toilet seats. The application is expanded to include computers, magnetic disk units and transformers in May 2004. |