| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / AOTS Malaysia training course | Malaysia |

|

Energy Saving Diagnosis and ESCO

|

|

January 12, 2006

Jiro Konishi Enetech Yokohama (LLC) |

|

Contents

|

|

| Audit on Energy Conservation of Factory (medium-sized factory) |

| Contents: 2 Framework of the system 3 Scheme and procedure 4 Check item of factory audit - 1 5 Check item of factory audit - 2 6 Check item of factory audit - 3 7 Check item of factory audit - 4 8 Industry type of the audited factory 9 Proposal by the audit report - 1 10 Proposal by the audit report - 2 11 Proposed energy conservation rate 12 Energy conservation rate by industrial type 13 Number of audits |

| Framework of the system |

| 1. Objects: factories of the scales falling

under type 2 designated energy management

factory Fuel = 1,500 to 3,000kL/y, electric power = 6 to 12 million kWh/y 2. Audit to be done in response to application by the auditee factory 3. Submission of the preliminary survey sheet on energy audit from the applicant 4. One-day onsite survey by two specialists, one in thermal energy and the other in electric power 5. Analysis of data and sending of the report 6. Energy audit done free of charge (administration's budget) 7. Nationwide endeavor (at ECCJ's 9 branches) 8. Items to be entered are standardized and statistical analysis is facilitated. 9. The auditee factory has no obligation to implement the proposals. 10. Questionnaire surveys one year after audit indicate that about 30 percent of the proposals are implemented. 11. Specialists are selected from those who have been registered in ECCJ. 12. The institution and procedure of energy conservation audit for buildings are the same as those of the factory energy conservation audit. |

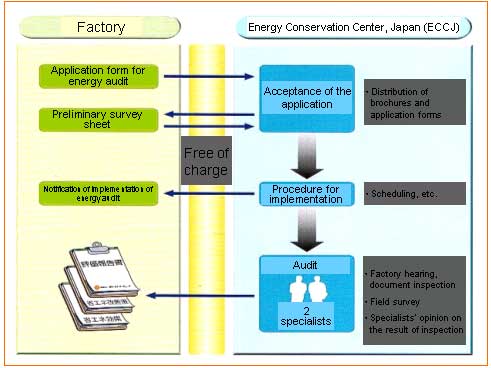

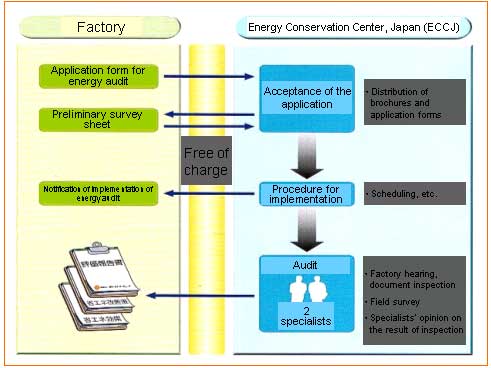

| Scheme and procedure |

|

| Check item of factory audit - 1 | ||

|

||

| 1. General administrative matter -Energy management system -State of implementation of measurement / recording -State of facility and equipment maintenance -Management of energy consumption -Energy unit consumption management for major products -Environmental conservation related management -Improvement of processes |

||

| 2. Air conditioning / refrigerating facility

-Operation management -Energy conservation measure -Operation management of cooling facilities -Operation management of auxiliary facilities I-nsulation / refrigerating facilities |

||

| Check item of factory audit - 2 |

| 3. Pump / fan, compressor -Operation management of pumps / fans -Operation management of the pneumatic system 4. Boiler / industrial furnace, steam system, heat exchanger, waste heat / wastewater, etc. -Combustion management -Operation / efficiency management -Insulation / heat insulation and prevention of heat radiation loss -Temperature control of exhaust gas -Operation management of steam -Management of steam leaks / insulation -Optimization of piping system -Leveling of load -Recovery and reuse of steam drain -Operation management of heat exchanger -Reduction of waste heat / wastewater |

| Check item of factory audit - 3 |

| 5. Substation facility, motor, lighting equipment,

electrical heating facility -Substation facility management -Transformer facility management -Motor capacity / operation management -Operation management of lighting equipment -Operation management of electrical heating facility 6. Improvement of processes -Improvement of the operation -Review of the factory processing line -Realization of efficiency improvement, continuous operation -Others |

| Check item of factory audit - 4 | ||

| 7. Leveling of load, electric power contract,

co-generation, new energy, etc. -Load leveling measure -Contract for control of demand and supply, etc. -Plan for introduction of co-generation, etc. -New energy, etc. -Energy conversion |

||

|

||

| 1/6 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

|

Copyright(C) ECCJ 1996-2019

|