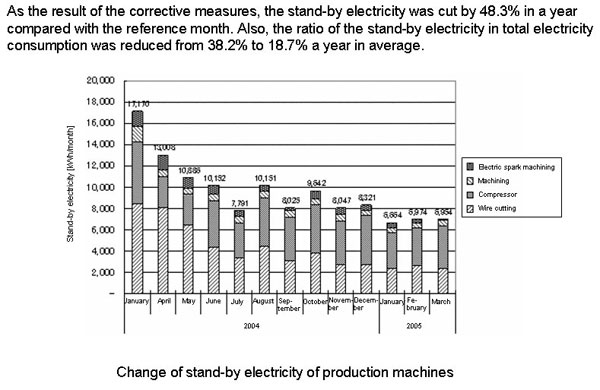

(4)-1 Stand-by electricity when machines are not used (consciousness of operators)

Electricity consumption had been known only at each factory until the problem was taken up. Even if machines were not used, the power supplies were left turned ON and stand-by electricity kept flowing wastefully. It had not been known how electricity was wasted and, therefore, how much was paid for wasteful consumption. Especially, when operators were busy or working overtime, they would leave the machines with the power switch turned on.

(4)-2 Waste of air compressors

After checking the electricity consumption in each hour, it was found that the increase of the consumption did not always correspond to the operation of machines which supply air. Even when it corresponded to the operation, electricity was consumed more than necessary. The reasons were as follows.

(a) Leakage due to aging of pipes.

(b) Request for air from machines which were not working (it was found that electric spark wire cutters periodically requested air even after finishing the process).

(c) Inconsistency between compressor and machine group (Piping was not made according to

operative conditions, so when only one machine was started at night, a big compressor would start).

(4)-3 Characteristics of electric spark wire cutter

It was not designed to automatically turn off the power switch after finishing processing. So it kept wasting the stand-by electricity until operators turned off the switch.

|