2) EE&C Technologies on Boiler/Steam System

| AEEC Home | Training Index | Index | Top | Previous | Next |

| METI / ECCJ / ACE Training Program MTPEC06 (2007.01) |

| (1) Industrial Furnaces

9) Heat Recovery Rates for Industrial Furnaces |

||||||||||||||||||||||||||||||||||||||||||||||||||||

Waste Heat Recovery Rates, Standard/Target for Furnaces

B: Rating capacity of from 21GJ/h (≈ 5Gcal/h) to under 84GJ/h (≈ 20Gcal/h) C: Rating capacity of from 840MJ/h (≈ 200Mcal/h) to under 21GJ/h (≈ 5Gcal/h) |

||||||||||||||||||||||||||||||||||||||||||||||||||||

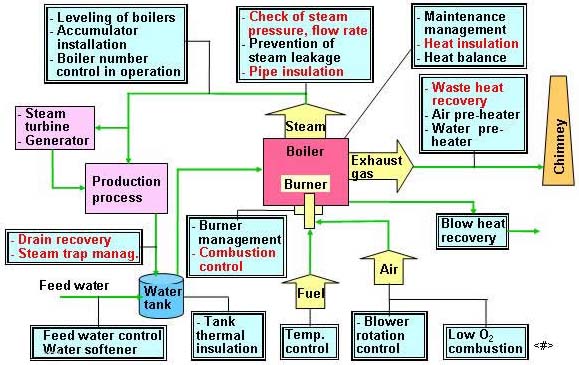

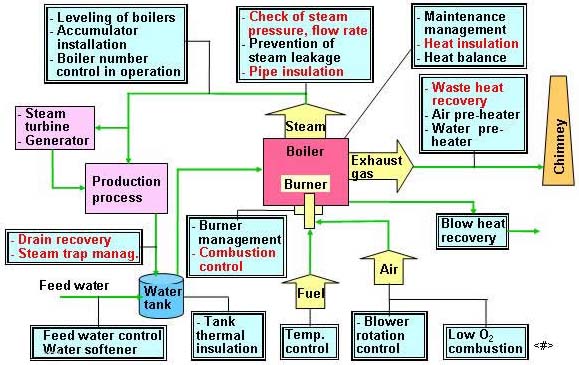

| (2) Boiler and Steam System 1) EE&C Measures on Boiler-Steam system |

|

| (2) Boiler and Steam System 2) EE&C Technologies on Boiler/Steam System |

|

| (2) Boiler and Steam System 3) Standard/Target Air Ratio for Boilers by the Law

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note *1: The standard values of air ratio mentioned in the table above define those to be obtained in measurements at the boiler outlet when fired at a constant level of load after regular inspection and in a stable states. Note *2: Air ratio = 21/[(21-(Oxygen content in the exhaust emission in percentage)] Note *3: In the case of the pulverized coal fired boiler |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/19 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |