4) Example of Power-saving by Speed Control

| AEEC Home | Training Index | Index | Top | Previous | Next |

| METI / ECCJ / ACE Training Program MTPEC06 (2007.01) |

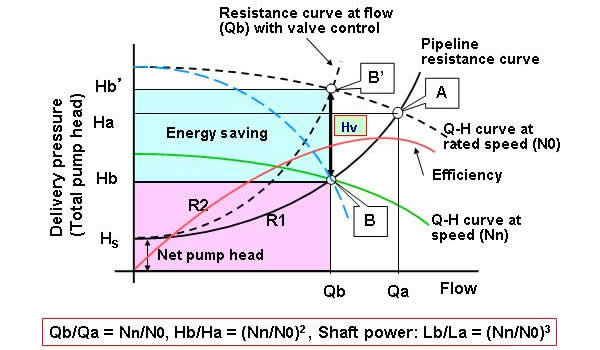

| (3) Pumps 4) Example of Power-saving by Speed Control |

|

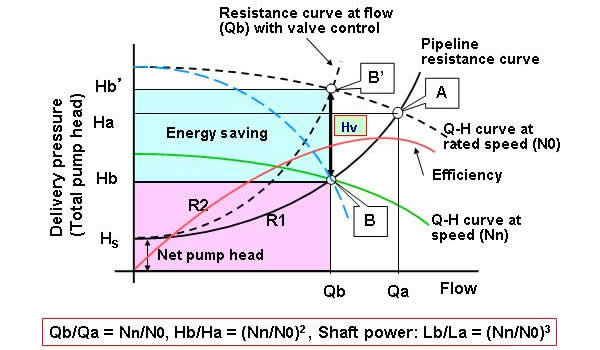

| (3) Pumps 5) Pump efficiency & Selection of pump capacity |

| (1) Employ a pump with appropriate capacity With respect to the pump efficiency at a flow rate of 70%, a pump with a capacity of 80 improves by approx. 10% more than pump with a capacity of 100. (2) Quantity control of pumps With respect to the pump efficiency at a flow rate of 40%, pumps with a capacity of 50 improve by approx. 30% more than pump with a capacity of 100. Controlling the quantity of pumps by installing several small capacity pumps in place of large capacity pumps results in energy savings.  |

| (4) Fans/Blowers

1) EE&C Measures on Fan/Blowers |

Installed capacity > Required capacity

Fan/Blower is very similar to pump, and the law of similitude is applied in these machines because of handling fluid. However, there is not the term of “Actual head” in Fan/Blower. Compressor handles the air as compressed gas, so the aspect of compressor differs from Fan/Blower. |

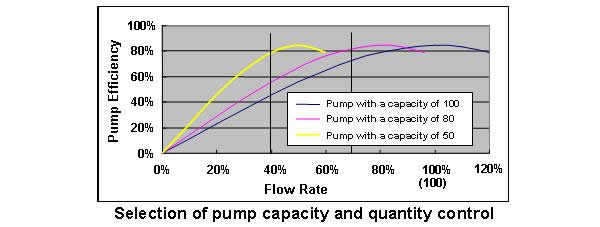

| (5) Air Compressors 1) Points of EE&C on Air Compressor |

|

| 13/19 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |