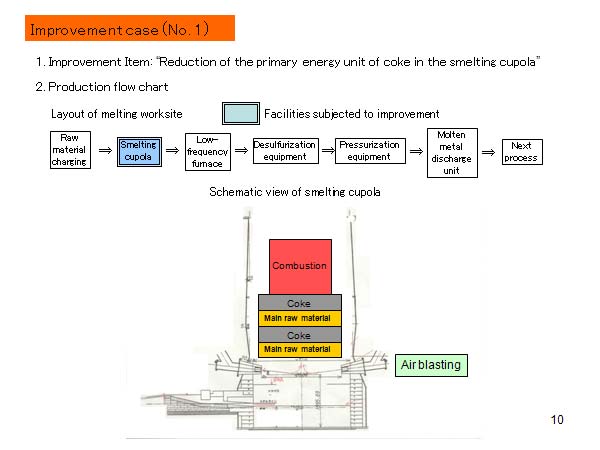

3. Reason of improvement

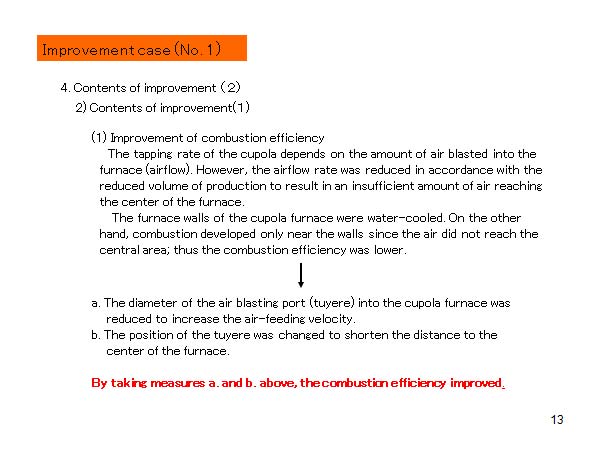

Along with the reduced production, the tapping rate per hour was reduced to half that of the conventional level (80 t/H to 40 t/H). The combustion efficiency in the cupola was consequently reduced, and the primary energy unit of coke was also aggravated.

In addition, the scrap content, which is used as the main raw material, increased among raw materials to result in a reduction in carbon content in the molten cast iron. (Though scrap is cheap, its carbon content is low.) Since combustion for melting with an increased amount of coke became necessary to compensate for such shortcoming, the primary energy unit of coke was further aggravated.

Under these circumstances, it became necessary to improve the operating conditions to lower the primary energy unit of coke

|