Scheme and procedure

| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / AOTS Philippines training course | Philippines |

|

Audit on Energy Conservation of Factory

Jiro Konishi Enetech Yokohama June. 10 2005 |

Content

|

|

Audit on Energy Conservation of Factory(medium-sized factory) |

| Contents: 2 Framework of the system 3 Scheme and procedure 4 Check item of factory audit - 1 5 Check item of factory audit - 2 6 Check item of factory audit - 3 7 Check item of factory audit - 4 8 Industry type of the audited factory 9 Audit report 10 Proposal by the audit report - 1 11 Proposal by the audit report - 2 12 Proposed energy conservation rate ?13 Energy conservation rate by industrial type 14 Number of audits |

Framework of the system |

Outline of the system

|

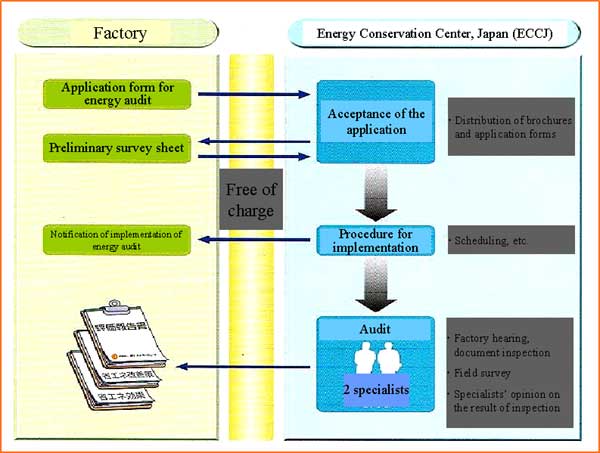

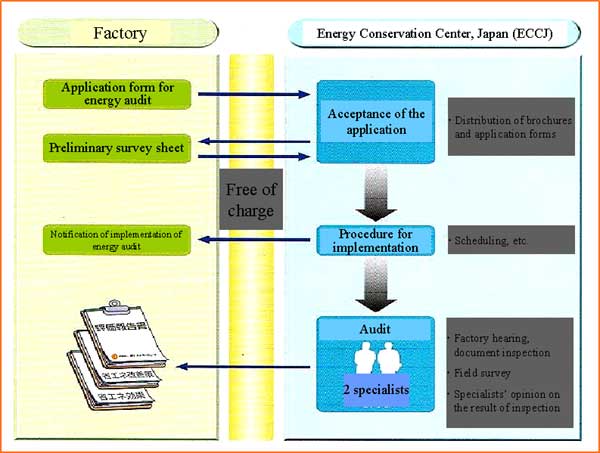

Scheme and procedure |

|

Check item of factory audit - 1 |

1. General administrative matter

|

| 1/11 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

Copyright(C) ECCJ 1996-2019 |