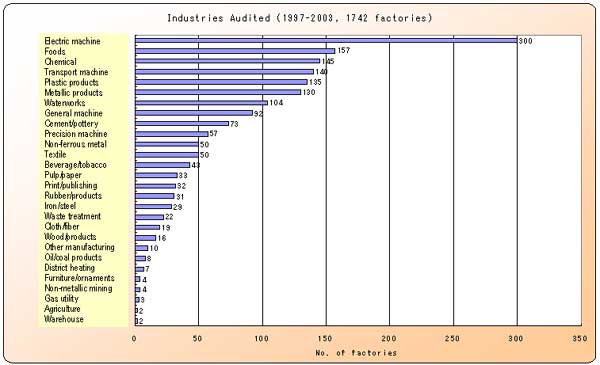

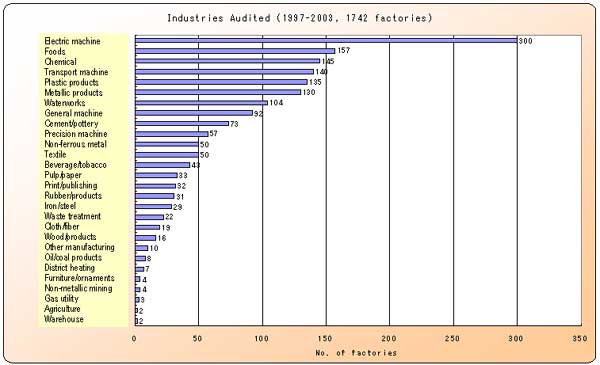

Industry type of the audited factory

Energy Conservation Guidebook for Factories, 2004-3 Edition

| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / AOTS Philippines training course | Philippines |

Check item of factory audit - 2 |

3. Pump / fan, compressor

|

Check item of factory audit - 3 |

5. Substation facility, motor, lighting equipment, electrical heating facility

|

Check item of factory audit - 4 |

7. Leveling of load, electric power contract, co-generation, new energy, etc.

|

Industry type of the audited factory |

Energy Conservation Guidebook for Factories, 2004-3 Edition |

Energy Conservation Guidebook for Factories, 2004-3 Edition |

||||||||||

(From the summary of questionnaire to the auditees in Fiscal 2002)

|

| 2/11 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

Copyright(C) ECCJ 1996-2019 |