-

5 Contents of corrective measures

5-1 Stand-by electricity when machines are not used (awareness of operators)

-

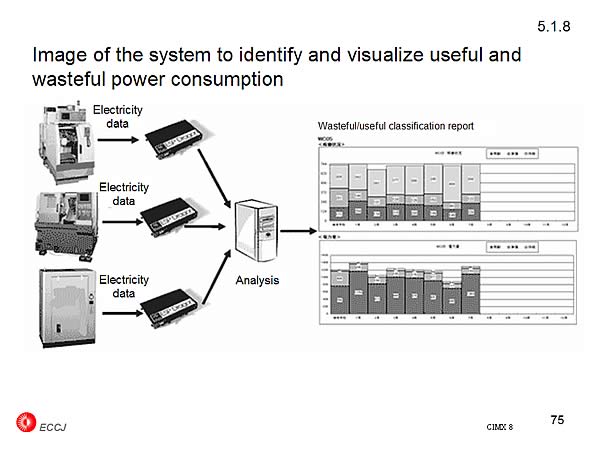

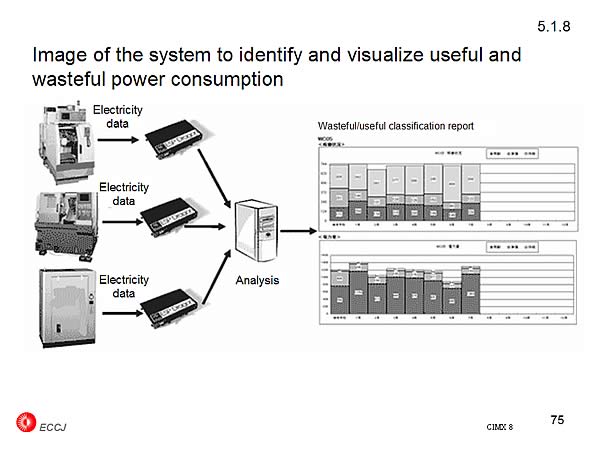

[1] The company installed electricity measurement devices on 100 electric machines, which are equivalent to 80% of electricity consumed in the company, and started to classify the electricity consumption into wasteful and useful using dedicated software.

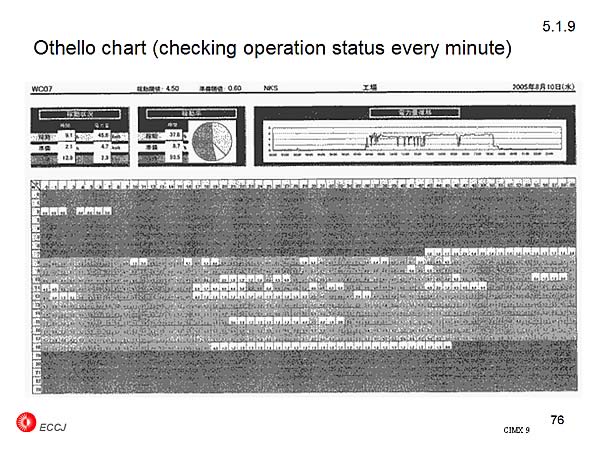

[2] Measurement was made every minute. Daily operation records and consumption of standby electricity were controlled for each equipment, using an operation control chart known as the “Othello Chart.”

[3] These data were compiled on monthly basis for each equipment. Additionally, performance record was strictly controlled as information on each equipment group.

[4] The company clarified the divisions which were good at cutting the standby electricity and the division which were not, comparing with the consumption in January 2004 as the reference point and gave the information to each operator with their pay slip.

[5] The electricity fee thus saved was equally distributed to each operator as “energy conservation dividend”.

[6] As a result, this system was supported by employee’s families and became encouragement for improvement activities.

- 5-2 Waste of compressors

-

As well as checking the joints of pipes, old pipes were changed to new ones. As a result, air leakage from pipes was eliminated, and air supply to machines which are not requesting air was minimized.

- 5-3 Mechanical characteristics of wire electric discharge machine

-

The design was changed to the one that automatically cuts the power supply after processing.

|