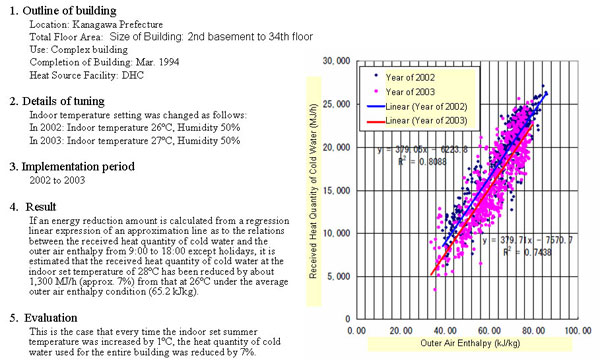

Alleviation of indoor temperature and humidity conditions

(In summer) excerpted from energy conservation tuning case sheet

(In summer) excerpted from energy conservation tuning case sheet

| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / AOTS Malaysia training course | Malaysia |

|

2.3.2 Rationalization of heating, cooling and heat transfer

|

(1) Management of heating, cooling and heat transfer 1) In the facility using heat media, manage the temperature, pressure and amount of heat media needed. 2) For industrial furnaces, improve heat patterns and enhance heat efficiency. 3) Manage the amount of things heated or cooled and their placement in the furnace, and avoid excessive or too low load. 4) If multiple pieces of equipment are used, adjust the load in a way that enhances the total efficiency of the equipment. 5) In the process where heating is repeated, shorten the waiting time between processes. 6) For the facility in which intermittent operation is possible, centralize the operation. 7) As for water supply to boilers, manage water quality based on JIS. 8) As for steam equipment, close valves when not used. 9) For steam of heating equipment, maintain adequate dryness of the steam. 10) Other matters that concern heating, heat media used, things that are heated, etc. |

|

2.3.3 Air conditioning equipment, hot water supply equipment, etc.

|

1) Manage air conditioning by limiting areas, managing blinds, etc. to reduce load. Also manage operation time, indoor temperature, ventilation, humidity, etc. of the facility according to operating conditions. Consider the cooling or heating temperature recommended by the government. 2) Manage thermal sources for air conditioning according to seasonal change of outside conditions to enhance the total efficiency of the facility. 3) If the thermal source for air conditioning is composed of several thermal source devices, try to enhance the total energy efficiency by adjusting the number of thermal equipment used and by selecting best equipment. 4) If air conditioning equipment is composed of several air conditioning machines in one area, enhance the total energy efficiency by adjusting the number of machines and by selecting best machines according to the state of the load. 5) As for hot water supply equipment, limit places to which hot water is supplied according to seasonal and working conditions, and improve the efficiency by managing hot water supply temperature, pressure, etc. 6) Regarding thermal source for hot water supply equipment, manage them in a way that enhances the total efficiency of the thermal source equipment including supplementary equipment such as pumps, etc. according to the change of load. 7) Regarding hot water supply equipment which is composed of several thermal sources, manage them to improve the total energy efficiency by adjusting the number of machines used according to the load conditions. |

|

Alleviation of indoor temperature and humidity conditions

(In summer) excerpted from energy conservation tuning case sheet |

|

|

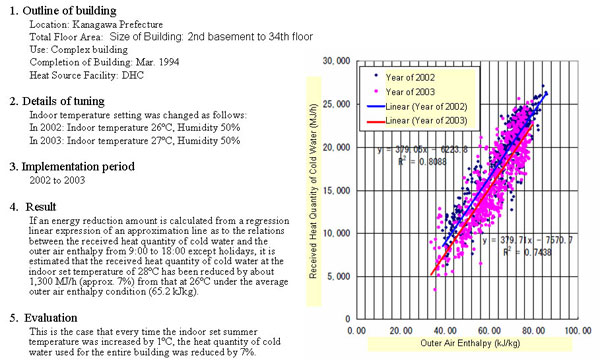

Control by co2 concentration

Excerpted from energy conservation tuning case sheet |

|

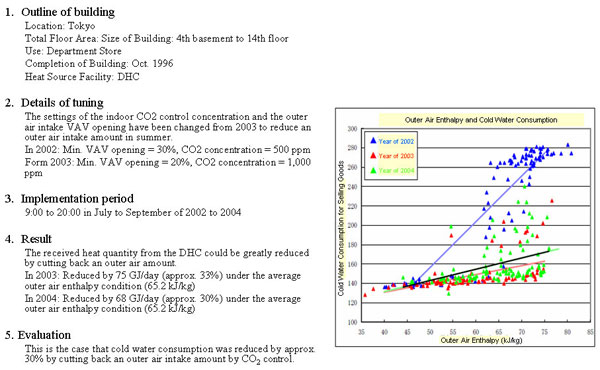

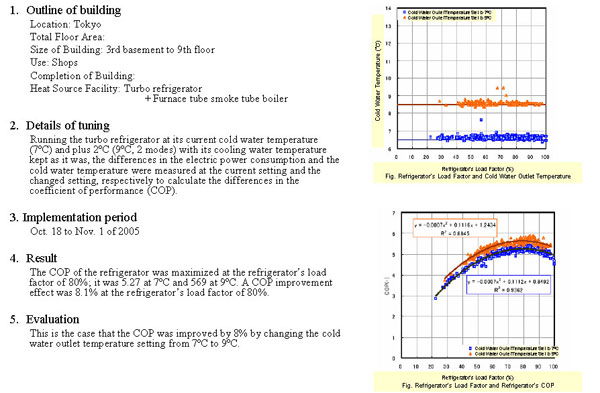

| Change to cold water outlet temperature setting Excerpted from energy conservation tuning case sheet |

|

|

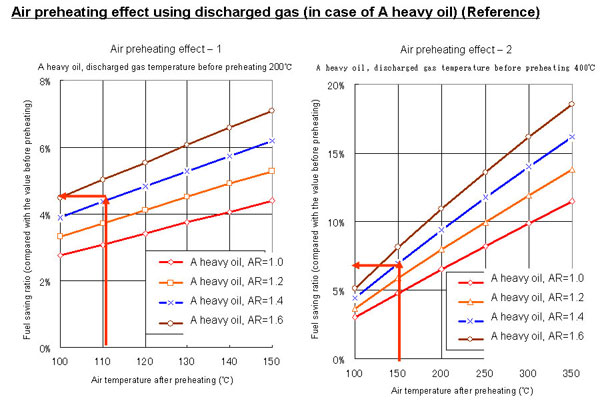

2.3.4 Recovery and utilization of waste heat

|

(2) Manage discharged gas temperature and waste heat recovery ratio based on the separate table 2(A). (3) Manage the temperature, quantity and nature of the steam drain. (4) Manage the scope to recover for heated solid or fluid according to apparent or latent heat, pressure, flammable component, etc. |

|

| 3/8 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

|

Copyright(C) ECCJ 1996-2019

|