1) EE&C Measures on Industrial Furnaces

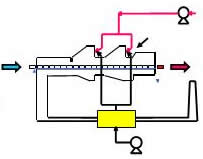

| (1) Combustion Management of Furnace a. Air ratio control (Oxygen measuring device) b. Fuel temperature control c. High efficiency burner (2) Furnace pressure control a. Seal of openings (Charging/discharging doors, others) (3) Insulation of furnace body, ducts (4) Waste heat recovery a. Preheating of combustion air (by recuperator) b. Regenerative burner (5) Heat loss reduction of cooling water (6) Improvement of heat pattern (7) Temperature control of heated material (8) Maintenance (Low down time, Yield up) (9) Check of SEC (Specific Energy Consumption) |

|