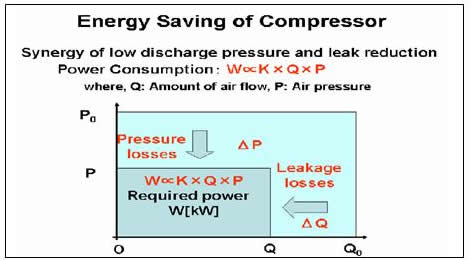

| (1) Reduction in discharge pressure |

| |

The actual discharge pressure (0.68MPa) should be lowered to 0.58MPa.

(required range is 0.45 to 0.5MPa ).

[Pressure reduction △0.1MPa is corresponding to △8% of fuel consumption.] |

| (2) Control of the number of compressors brought into operation & installation of receiver tank |

| |

Currently, 6 compressors are turned on and off separately at their pressure settings. � The number of compressors brought into operation should be controlled in accordance with load conditions. This will reduce power consumption, and cut down the maintenance cost.

[The receiver tank will reduce the pressure fluctuation caused by load change.] |

| (3) Prevention of air leakage |

| |

The main stop valve of each unused air pipe is closed, as is the air valve of each non-operating machine.

[Generally, the air leakage is more than 10%, sometimes it reaches to 20% in factory. Total air leakage should be reduced less than 5% by proper maintenance.] |