| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / Text for Training Courses | Thailand |

4. Electric Power Devices |

(1) Management of electric power equipment, electric heating equipment, etc. 1) Stop electric power equipment considering the correlation with starting power so that electric loss due to dry run is reduced. 2) When multiple motors are used, maintain adequate demand ratio, adjust the number of motors that runs, and implement adequate distribution of load. 3) Regarding fluid machines, optimize discharging amount and pressure and reduce the load of motors by reviewing the end pressure and discharging pressure and by controlling the number of machines. 4) Regarding induction furnaces, etc., improve heat efficiency by correcting filling method, etc for things to be heated. 5) Regarding electrolysis facilities, improve electrolysis efficiency by adequately managing distance between electrodes, density of electrolysis liquid, etc. 6) Manage voltage, current, etc and reduce electric loss for each electric facility. |

|

|

|

4.2.4 Example of management standards for boiler's water supply pumps(1)

|

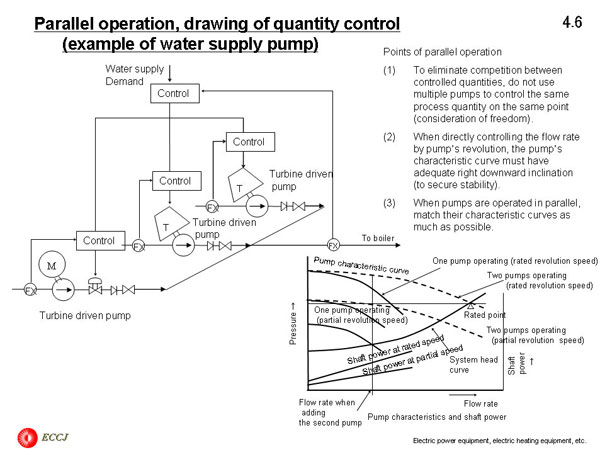

(1) After low pressure systems are cleaned and starting conditions has become ready, start motor driven pumps. (2) Start the first turbine driven pump when boiler's load is 25% or above. When boiler's load is 30% or above, stop the motor driven pump. (3) Start the second turbine driven pump when boiler's load is 45% or above. (4) Use one pump when boiler's load is 40% or below. (5) After all burners are turned off, stop the pump according to operator's judgment. (6) When using two pumps, operate them with same flow rate. 2. Operation of discharging pressure (1) When there is rated load, adjust boiler's output in a way that makes turbine's inlet pressure 25MPa (±0.3MPa). (2) When there is partial load, adjust boiler's output in a way that makes turbine's inlet pressure correspond the load. Management value is setting pressure±0.3MPa. 3. Management of motor voltage Manage bus line voltage of distribution board, because it is normally difficult to measure terminal voltage of motors. Management value: 6,300 - 6,600V |

|

| 4/8 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |

| Copyright(C) ECCJ 1996-2019 |