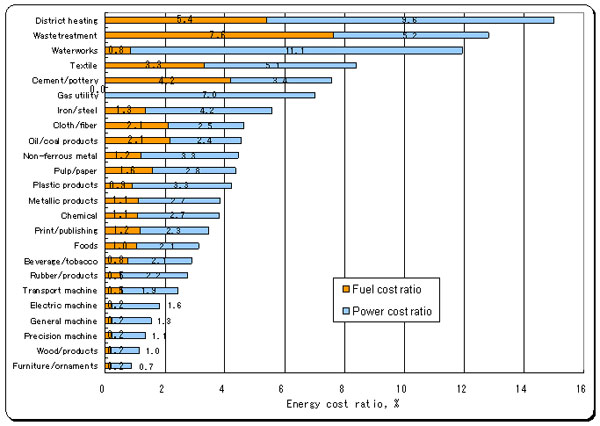

1-7.Energy cost ratio by industry type

| AEEC Home | Training Index | Index | Top | Previous | Next |

| ECCJ / TextReport | Vietnam |

1-7.Energy cost ratio by industry type |

|

| Energy Conservation Guidebook for Factories, 2006.3 |

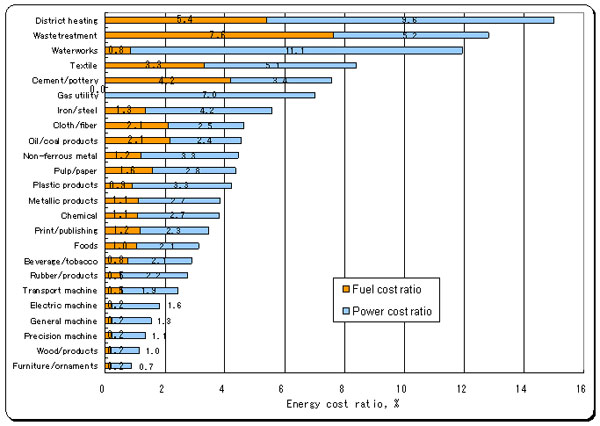

1-8.Number of audits |

|

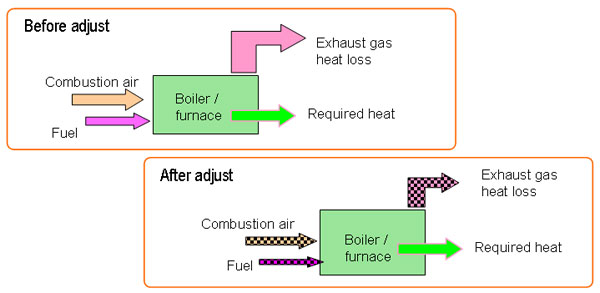

2. Energy Conservation Technology – combustion control and heat insulation |

|

2-1.Optimization of air ratio |

|

|

| 4/13 Next |

| AEEC Home | Training Index | Index | Top | Previous | Next |