Observation of on-site energy conservation audits and discussion of the results in “TOT under Qualified Energy Manager Training Project” in Vietnam

<Dispatch of experts>

Under the instruction and financial support of the Ministry of Economy, Trade and Industry (METI) (in the project for contributing to the rational use of energy in developing nations and the EE&C capacity building program), the Energy Conservation Center, Japan (ECCJ) observed and provided guidance for an energy conservation audit implemented at a Vietnamese smartphone and tablet exterior body manufacturing plant in as part of the training of trainers (TOT) under the AJEEP (ASEAN-Japan Energy Efficiency Partnership) Scheme 2 Qualified Energy Manager Training Project on October 10, 2019.

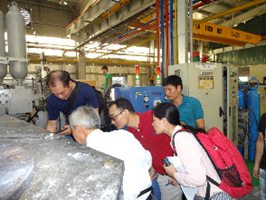

(1) At the machining plant, ECCJ gave explanations of the energy conservation audit and implemented audit observation.

(2) Trainers measured the electric furnace wall temperture, collected electric power analysis data, conducted luminous intensity investigations, and measured the cooling water piping temperatures.

(3) Together with the persons in charge at the audit target factory and trainers who had been certified in the previous fiscal year, ECCJ held a meeting about the audit reporting plan.

|

|

|

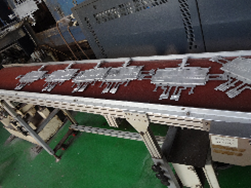

| Electric furnace wall temperature measurement | Smartphone exterior body injection molding situation | |

|

|

|

| Electric power measurement | Luminous intensity measurement | Audit reporting plan meeting |

(1) At the machining plant, electric furnace wall temperature measurements, electric power analyses, and luminous intensity measurements were implemented based on advance written questions.

(2) The guidance presented by the ECCJ experts was given in data analysis using the energy intensity considering changes in production quantities and utilization rates.

(3) As energy conservation proposals, ECCJ presented a proposal to reduce electric power consumption by introducing sequencers and inverters, and following consultations with the factory side, guidance was given to realize the final energy conservation proposal.

(4) The previous fiscal year’s certified trainers gave advice during the audit, and ECCJ was able to confirm their activities as trainers.

* AJEEP: ASEAN-JAPAN Energy Efficiency Partnership

Program for building EE&C capacity in the ASEAN region by dispatching experts and implementing training in Japan